Definition

Spreading is a process where the lengt of the Material increases, whilst the cross section decreases

When you spread the wideness of the Workpeace its called widening. when you spread the length its called spreading or lengthning

Different Process of Spreading:

The most basic way is to just forge between the hammer an the Flat side of the anvil. If you want to spread the Material more agressively, you can use the horn, or even the edge of the anvil. If you alredy have some tools, you can also use a kehlhammer with a kehlgesenk.

Heating up the Metal:

heat up the Metal slow and evanly, so that the Metal spreads smothly

if you heat it up to fast, the inner part stayes cold, and it cant move fluently. Tension can happen.

Sharpening

sharpening means spreading out the Material lengthwise of the workpeace, whilst the thickness decreases evenly

The cutting length of the Workpeace is always half of the length of the final tipp:

Formula: l= length of the Tip/2

However if you want to spread out both sides of the Material the Formula for the cutting length is different: l=length of the Tip/3

To forge a 3-dimensional tip, you need to turn the Material 90 degrees after every hit

if its not exactly 90 degrees, the tip gets unprecise

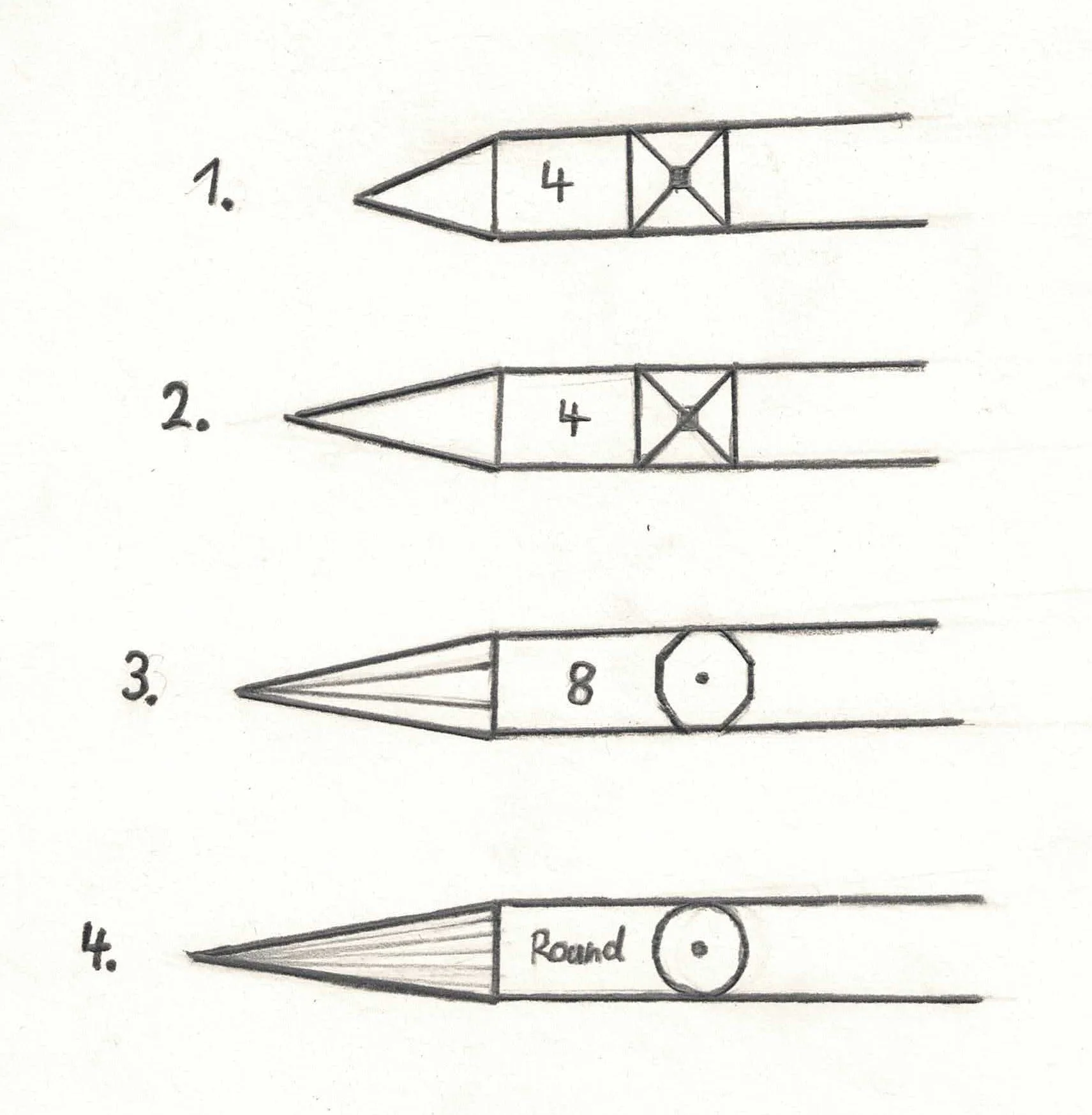

Steps to forge a tip

start with a short tip on al four sides

make it larger

forge it to eight sides

then forge it round

As soon as you have larger diameters you need to forge it to 16 sides before you forge it round, because the sides get bigger

-

Füge hier eine Zusammenfassung oder eine Liste hilfreicher Ressourcen hinzu.